An Iowa State duo adapts a 1990s ISU invention for the future of electronics manufacturing

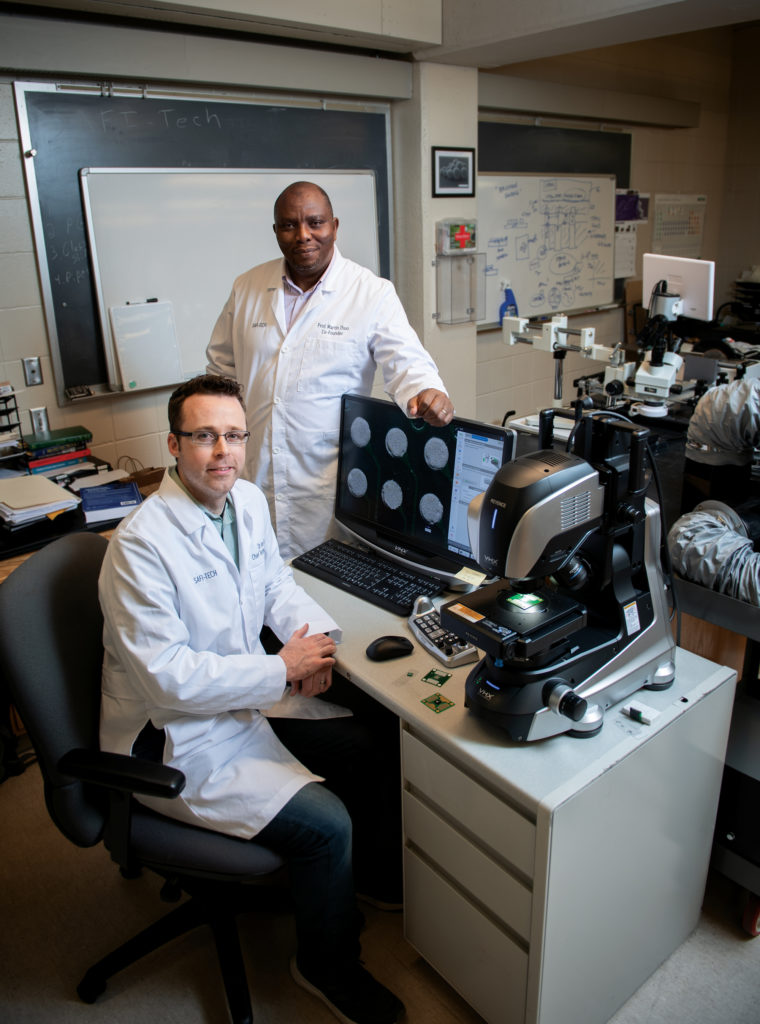

SAFI-Tech was founded from a partnership between Ian Tevis, a then postdoctoral student at Iowa State University, and the researcher he came to study under, Martin Thuo, assistant professor of materials science and engineering.

Thuo says in essence, materials science is “finding utility for whatever nature provides or whatever you can make,” and the SAFI-Tech co-founders decided in December 2015 to update a material that already had utility for the modern digital age.

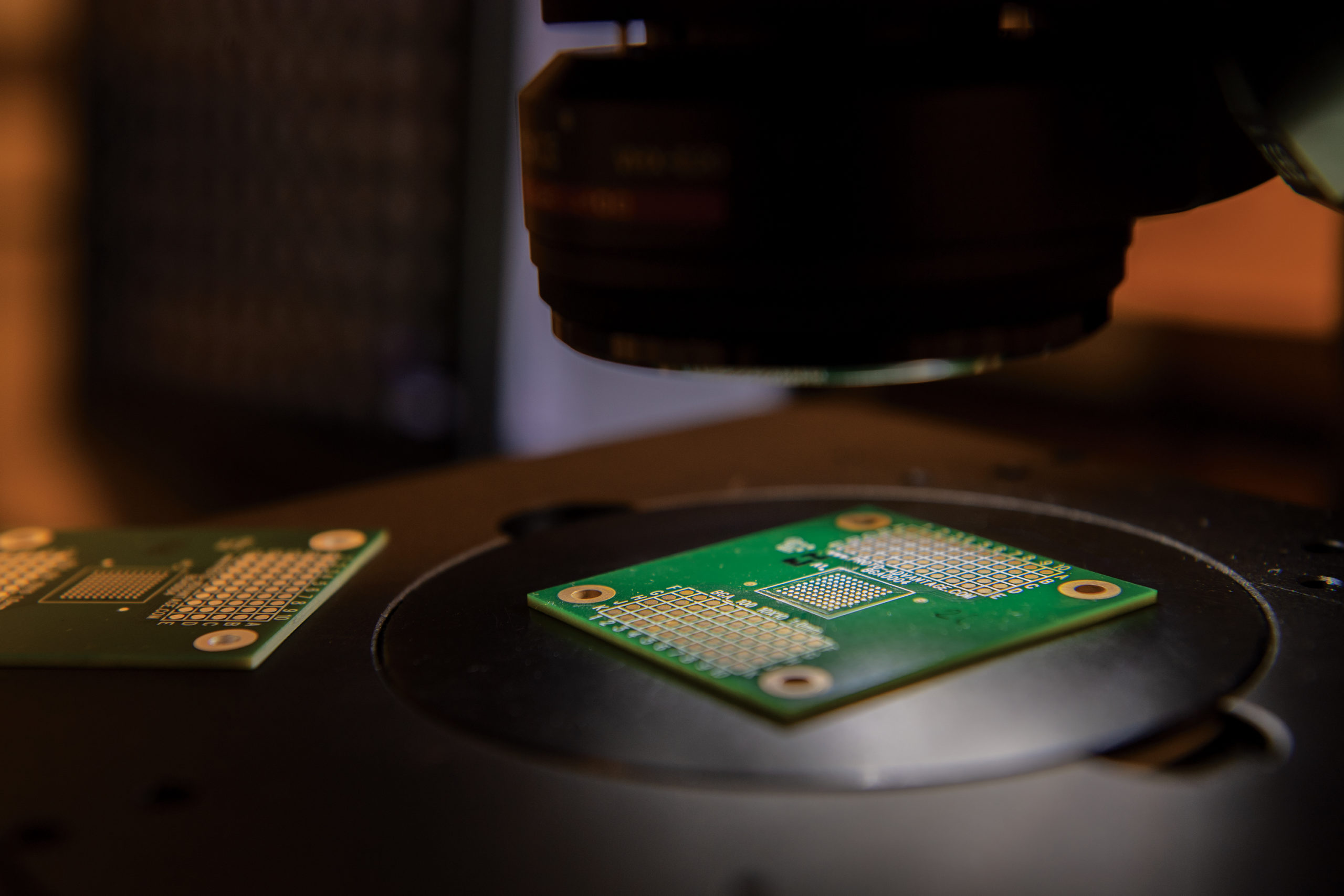

SAC305 is the name for the lead-free solder alloy most commonly used for electronics manufacturing, and it happened to be invented and patented in the U.S. by Iowa State professors and their colleagues in the 1990s. (Soldering is the process of joining metals using another, different metal with a lower melting point.) By the time the patent on SAC305 expired in 2013, the invention was licensed by companies in 13 countries and generated more than $58 million in royalties.

Tevis said it was the push for lead-free alloys that brought SAC305 to market. It became the primary alloy that everyone in electronics manufacturing is familiar with, but Tevis and Thuo took it back into the lab to fix one problem: temperature.

Soldering requires heating an alloy to its melting point, which for SAC305 is 473 degrees Fahrenheit. Using a technique they describe as “super-cooling,” Tevis and Thuo are the first to develop a new version of SAC305 called No-Heat SAC305 that can be used for soldering at 65 degrees Celsius, or about 150 degrees Fahrenheit, lower “than anybody could possibly imagine.”

As technologies use more wearable materials and move away from metals, Thuo said SAFI-Tech’s adaptation will ensure nonmetal components don’t melt during the manufacturing process.

Another priority of the No-Heat SAC305 is promoting energy efficiency, as the lower temperature requirement saves energy over time and wasted materials. The connection to the green technology mission is in the SAFI-Tech name as well — Thuo, who is originally from Kenya, said the word “safi” in Swahili happens to mean clean.

The startup transitioned from the lab to commercialization in January 2016 and is now affiliated with the Iowa State University Research Park with lab space on campus.

Tevis and Thuo have found angel investors for SAFI-Tech through the ISU Startup Factory and have received funding or other support from the Regents Innovation Fund, the National Science Foundation’s Small Business Innovation Research program and the Iowa Economic Development Authority.

The following Q&A is with Tevis and Thuo. It has been edited and condensed for clarity and brevity.

Can you briefly explain how you make SAFI-Tech’s No-Heat SAC305 alloy?

Thuo: We take metal, we melt it and then we break it down into particles. But as we break them out, we put a beautiful, very well-designed shell around the metal droplets. That shell forms a barrier to things that may promote solidification. It keeps the metal from freezing and then cools it down. That shell is the magic in the SAFI-Tech technology. Ian was very meticulous in executing all those and developing a very beautiful science. It’s such that we can layer different types of components on top of our liquid as it is forming into droplets and put all these layers on it, and those layers are enough to make them not turn into a solid.

How specifically is SAFI-Tech’s invention a more sustainable solution?

Tevis: The green aspect of this is really in the temperature of the ovens. Usually they have what’s called an inline reflow oven. It looks just like a pizza oven, except that in industry, those are like 30 feet long and they have 12 different zones in them and they’re going as quickly as they can. So when you turn the oven down to a lower temperature by using our material, off the bat, you get the energy savings. If you’re running the oven for 20 hours a day, you get the energy savings of running it at a lower temperature and you can continue to use your oven at the same speed and maybe even go a little bit faster. There could be defects that would occur at high temperatures, and so you’re not scrapping as much stuff because you’re doing it at a lower temperature. Our solder joint will be indistinguishable from a regularly made SAC305 solder joint. They can just put it through the same exact recycling process to get the solder metal out, so I consider that green too, because many new technologies use these esoteric materials that just complicate the end of life of these products.

Thuo: The other thing I think we have is SAC305 is already out in the market. We know about its safety. Since we’re not changing the alloy, we don’t have to worry about, “Is this material going to have different health issues compared to what we already know?” We have the alloy in our computers. We have it in our phones, it’s everywhere, so we know it’s working well for everybody.

Tell me more about the experience of developing a technology that was first-of-its-kind.

Tevis: It has been a challenging road with a fair amount of dead ends. You can’t just call up a buddy and get their advice, because no one does it. No one in the world can do what we do. There’s a lot of market opportunities for the technology, so a lot of it has been kind of hopping between what our customers have been saying. We try to address them, but there’s a big field and the goal we’ve really narrowed down on in SAFI-Tech is replacing all lead-free solder with our material and all new assemblies with our material.

Thuo: The excitement of getting the discovery from an idea on a whiteboard in my office and looking at all the science and going back and forth with Ian and saying, “This should work.” You move from hypothesis to you making a small, tiny product that has that behavior — that, I won’t lie, is very exciting. Your heart, it shoots up. Ian and I sitting in that office, middle of December in Iowa, and it’s cold but it feels warm. Then the reality hits you. OK, now that we have it, how do we get to the market? When you have a platform technology, the problem is not the invention. The problem is finding who needs it and who will use it and who has the most pain to pay for it. That’s the challenge now where the company comes in, because from a professor point of view, the excitement of the innovation is done. Now make a product, right? A professor can make one gram of material but no industry cares about one gram. So what? The “so what” question is where the work comes in. Ian and I have been working, and let me say Ian mostly, has been really pushing this to get in front of the industry.

Given how supply chain disruptions have affected electronics manufacturing, could SAFI-Tech’s technology help streamline the supply chain whether or not a pandemic is causing problems?

Tevis: There’s a push for bringing semiconductor manufacturing on shore. For the pitches, by pitches I mean how closely electronic components are getting together, soldering becomes really challenging for semiconductors because they’re extremely thin and when you heat those up, they start to curl. When it starts to curl at really high temperatures, it actually physically separates the semiconductor from what it is being attached to and that makes it basically impossible to do high-scale, quick, high-density manufacturing because you’re going to get a lot of scrap and you’re not going to make these solder joints. So SAFI-Tech wants to get plugged into this onshoring of semiconducting manufacturing because they’re going to need a unique technology that doesn’t rely on other countries. We’re U.S.-based, U.S.-patented technology, and they’re going to need us to really jump ahead of the next generation that’s going to be done overseas because no one else can do what SAFI-Tech can do.

Thuo: As far as supply chain is concerned, one of the challenges we have in electronic manufacturing is the cost to entry. For you to create a fabrication lab right now, it is billions of dollars’ worth of technology, but with our technology we can start opening affordable production lines that don’t have to rely on such capital intensive processes.

What makes an innovation in materials science possible?

Thuo: From my side, I will say I’m a professional tinkerer. If somebody has a problem, and they are bold enough to give it to me or to share with me, I’ll try and solve it. Will I be successful? Maybe, maybe not. Material science at the core of it is you’re trying to find solutions. You’re trying to enable capabilities and you have all the elements in the world to put wherever you want. The problem is not whether you can solve it, or you can find a solution for it. Everybody is creative, but not everybody is innovative. We can create a lot of possible solutions, but then when you come to innovation, you have to worry about costs, you have to worry about scale-up. You have to worry about other logistic issues that solving that problem in the lab may not appeal to any other company out there.

So for me it’s getting access to knowing what somebody is struggling with and trying to see, do we have a pathway to solve that problem? Here with SAFI-Tech was a 5,000-year problem that we found needs a little bit of modification, an update, and we had a good idea. Ian and I were sweating on this for quite some time. It’s not that we sat one day and figured it out. It was quite a bit of work and a lot of ideas going back and forth until you get to that point where you have something that is promising.

Tevis: I think that to bring it back to Martin’s point about the function, to bring a material science product to market, you have to demonstrate function. That’s what the customers will care about. Then finding the funding to support you as a startup to get there.

What are SAFI-Tech’s goals over the next few years?

Tevis: We spent the last six years getting to this point where we can showcase the function of the technology, and so our goal over the next two years is to bring forward a SAC305 product, specifically designed for a use case — we’re not sure which use case that will be — and hopefully with a larger materials partner, a partner that knows how to bring large-scale materials to market and in the electronics space, which is very rigorous and extremely cost-sensitive. In two years, we should have that product being integrated into assembly processes.